Stepper Motor Interfacing with 8051 Microcontroller (AT89C51) – Circuit Diagram & Source Code

Introduction

Stepper motor interfacing with 8051 microcontroller (AT89C51) is one of the most important and frequently asked embedded systems projects for engineering students. Stepper motors are mainly used where accurate position and speed control is required.

In this tutorial, you will learn how to interface a stepper motor with 8051, understand the working principle, ULN2003 driver circuit, and step-by-step control logic. This project is ideal for diploma, B.Tech, M.Tech, and embedded systems training students.

What is a Stepper Motor?

A stepper motor is an electromechanical device that converts electrical pulses into precise mechanical rotation. Each pulse moves the motor shaft by a fixed angle, making it ideal for precision control applications.

Key Features of Stepper Motor

High accuracy and repeatability

Precise angular movement

Open-loop control (no feedback required)

Easy to interface with microcontrollers

Why Use 8051 Microcontroller (AT89C51)?

The AT89C51 microcontroller is one of the most widely used controllers in academic and industrial training projects.

Features of AT89C51

8-bit microcontroller

4 KB Flash memory

128 bytes RAM

32 programmable I/O pins

Timer and interrupt support

Components Required

AT89C51 Microcontroller

Stepper Motor (Unipolar)

ULN2003 Driver IC

11.0592 MHz Crystal Oscillator

Capacitors (33pF)

5V DC Power Supply

Connecting wires and PCB/Breadboard

Why ULN2003 Driver IC is Used?

The 8051 microcontroller cannot drive a stepper motor directly due to current limitations. The ULN2003 IC acts as a current amplifier between the microcontroller and the stepper motor.

Advantages of ULN2003

High current driving capability

Built-in flyback diodes

Protects microcontroller from back EMF

Easy interface with 8051

Working Principle of Stepper Motor with 8051

The stepper motor rotates when its coils are energized in a specific sequence. The 8051 microcontroller sends control signals to the ULN2003 driver, which energizes the motor coils accordingly.

Changing the sequence → changes direction

Changing the delay → controls speed

Pin Configuration

Port P2.0 – P2.3 → ULN2003 input pins

ULN2003 output pins → Stepper motor coils

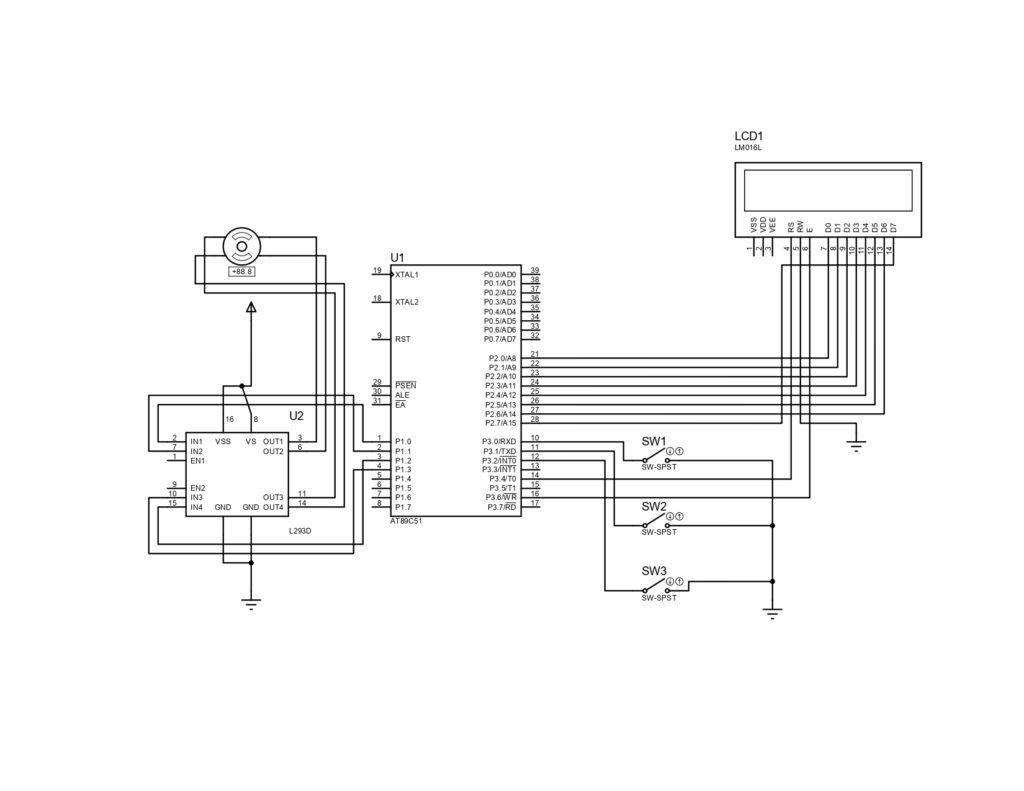

Circuit Diagram of Stepper Motor Interfacing with 8051

Below is the circuit diagram for Stepper Motor Interfacing with AT89C51 Microcontroller.

Source Code for Stepper Motor Interfacing with 8051

The following program rotates the stepper motor using a full-step sequence.

#include<reg51.h>

#define lcd P2

sbit rs=P3^4;

sbit rw=P3^5;

sbit e=P3^6;

sbit sw1=P1^2;

sbit sw2=P1^1;

sbit sw3=P1^3;

sbit sw4=P1^0;

sbit forward = P3^0;

sbit backward = P3^1;

sbit stop = P3^2;

void delay (int);

void cmd (unsigned char);

void display (unsigned char);

void string (char *);

void init (void);

void delay (int d)

{

unsigned char i;

for(;d>0;d--)

{

for(i=250;i>0;i--);

for(i=248;i>0;i--);

}

}

void cmd (unsigned char c)

{

lcd=c;

rs=0;

e=1;

delay(10);

e=0;

}

void display (unsigned char c)

{

lcd=c;

rs=1;

e=1;

delay(10);

e=0;

}

void string (char *p)

{

while(*p)

{

display(*p++);

}

}

void init (void)

{

cmd(0x38);

cmd(0x0c);

cmd(0x01);

cmd(0x80);

}

void main()

{

int z=0;

init();

P3=0xff;

P1=0x00;

abc:

cmd(0x80);

while(stop==0);

string("Press Forward Or");

cmd(0xc0);

string("Backward To Run");

forward=1;

backward=1;

while(1)

{

if(forward==0)

{

cmd(0x01);

cmd(0x80);

string("Running Forward");

while(forward==0);

while(1)

{

z++;

if(z==1)

{

sw1=1;sw2=0;sw3=0;sw4=0;delay(30);

if(backward==0 || stop==0)

break;

}

else if(z==2)

{

sw1=1;sw2=1;sw3=0;sw4=0;delay(30);

if(backward==0 || stop==0)

break;

}

else if(z==3)

{

sw1=0;sw2=1;sw3=0;sw4=0;delay(30);

if(backward==0 || stop==0)

break;

}

else if(z==4)

{

sw1=0;sw2=1;sw3=1;sw4=0;delay(30);

if(backward==0 || stop==0)

break;

}

else if(z==5)

{

sw1=0;sw2=0;sw3=1;sw4=0;delay(30);

if(backward==0 || stop==0)

break;

}

else if(z==6)

{

sw1=0;sw2=0;sw3=1;sw4=1;delay(30);

if(backward==0 || stop==0)

break;

}

else if(z==7)

{

sw1=0;sw2=0;sw3=0;sw4=1;delay(30);

if(backward==0 || stop==0)

break;

}

else if(z==8)

{

z=0;

sw1=1;sw2=0;sw3=0;sw4=1;delay(30);

if(backward==0 || stop==0)

break;

}

}

}

if(backward==0)

{

cmd(0x01);

cmd(0x80);

string("Running Backward");

while(backward==0);

while(1)

{

z++;

if(z==1)

{

sw1=1;sw2=0;sw3=0;sw4=1;delay(30);

if(forward==0 || stop==0)

break;

}

else if(z==2)

{

sw1=0;sw2=0;sw3=0;sw4=1;delay(30);

if(forward==0 || stop==0)

break;

}

else if(z==3)

{

sw1=0;sw2=0;sw3=1;sw4=1;delay(30);

if(forward==0 || stop==0)

break;

}

else if(z==4)

{

sw1=0;sw2=0;sw3=1;sw4=0;delay(30);

if(forward==0 || stop==0)

break;

}

else if(z==5)

{

sw1=0;sw2=1;sw3=1;sw4=0;delay(30);

if(forward==0 || stop==0)

break;

}

else if(z==6)

{

sw1=0;sw2=1;sw3=0;sw4=0;delay(30);

if(forward==0 || stop==0)

break;

}

else if(z==7)

{

sw1=1;sw2=1;sw3=0;sw4=0;delay(30);

if(forward==0 || stop==0)

break;

}

else if(z==8)

{

z=0;

sw1=1;sw2=0;sw3=0;sw4=0;delay(30);

if(forward==0 || stop==0)

break;

}

}

}

if(stop==0)

goto abc;

}

}

Algorithm

Initialize Port P2 as output

Send step sequence to motor coils

Provide suitable delay

Repeat sequence for continuous rotation

Applications of Stepper Motor with 8051

Robotics and automation systems

CNC machines

3D printers

Industrial control systems

Camera positioning systems

Advantages

High precision control

Simple hardware design

Low cost

Reliable operation

Conclusion

Stepper motor interfacing with 8051 microcontroller (AT89C51) is an essential embedded systems project that helps students understand motor control, driver circuits, and microcontroller programming. This project is highly recommended for academic practicals and final-year projects.

You can further enhance this project by adding:

LCD display

Direction control switch

Speed control using potentiometer

1 Response

[…] Previous story Stepper Motor Interfacing with 8051 Microcontroller (AT89C51) – Circuit Diagram & Source Code […]